Cavity Wall Insulation

Request a free consultation

Bel mij terug

Gratis, vrijblijvend advies

Cavity-wall-insulation

- Energy saving

- Fast payback period

- Better living comfort

- Environmentally friendly

- More favorable energy label

- Insulation subsidy

What is cavity wall insulation?

Cavity wall insulation is applying the insulation material in empty areas between the inner wall and the outside wall of a house or premises. The empty area between the inner and outside wall is called ‘’cavity’’. By insulating this area it is known as cavity wall insulation.

Houses that are built between 1924 and 1975 have from construction no cavity wall or floor insulation. Pass through the oil crisis which arose in 1973 and lasted until 1974 people became aware of doing more in the field of energy saving. From 1976 the first houses were immediately fitted with cavity wall insulation during construction.

When is cavity wall insulation possible?

If a house has a cavity wall then should cavity wall insulation be possible. The first question to be asked is: Does my house has a cavity wall? Generally you can assume that if your house is built after 1928 your house has a cavity wall. You can also measure the distance between the in and outside of your facade. You can do this by sticking a ruler or folding rule through the open butt joints in your outer wall. The distance you measure should around 26 centimetres. If your house has a cavity wall, the following assessment points need to be checked:

Is the cavity wall clean enough? Is the cavity wall wide enough? What about the condition of the facade? The answers on these questions are different per house. That is why before a cavity wall insulation is carried out, a visual inspection must be carried out by a cavity wall insulation counsellor. Request for a Free cavity wall insulation check here.

How does the cavity wall insulation get applied?

It’s important to know that applying cavity wall insulation isn’t a do-it -yourself job. Cavity wall insulation always get applied by qualified insulation fitters. In addition, an insulation consultant has determined in advance that the facades can be insulated without any problems.

Methods of applying cavity wall insulation.

The insulation engineer always starts with a visual facade inspection to check again for details. Then the insulation engineer starts drilling holes at various intersections in the joint. A fixed drilling pattern is used, so that an optimal distribution is achieved during the blow-in of the insulation.

Once the house has been drilled out, you can start filling the cavity with insulation material. The fitter always start at the bottom boreholes and then works slowly towards the top boreholes. The insulation is blown into the cavity wall by a special blow-in machine. On this blow-in machine there is an automatic switch-off that indicates when the room in question has been blown full of insulating material. This way, the insulation engineer knows that that part of cavity is filled, and the nozzle is placed in another drill hole.

After the facade is completely filled with insulation, all drill holes are closed again with grout. The mechanics mix this grout by colour so that this colour corresponds well with the current grout colour of the house in question.

What types of cavity wall insulation are there?

There are many different insulation materials used to insulate the cavity wall. The most common insulation materials are described below:

Glass wool cavity wall insulation: This insulation material consists of 80% recycled glass and

20% sand. Within the glass wool cavity wall insulation, different types and brands are

available. The glass wool is blown into the cavity wall in flake form. Plus insulation uses the

certified Knauf Supafil blown-in wool. It meets the highest standards and quality

requirements.

EPS cavity wall insulation: EPS stands for expanded polystyrene. Also popularly known as

Styrofoam. The insulation material consists of small polystyrene balls. These EPS beads

consist mainly of hydrogen and carbon. The insulation beads are blown into the cavity wall

together with a special adhesive.

HR isofoam cavity wall insulation: HR isofoam consist of two components, one component

resin and one component hardener. Both components are poured into the cavity wall. The

components harden out and form seamless insulation plate in the cavity wall. This process is

done in a environmentally friendly way without the use of CFC’s and HFC’s.

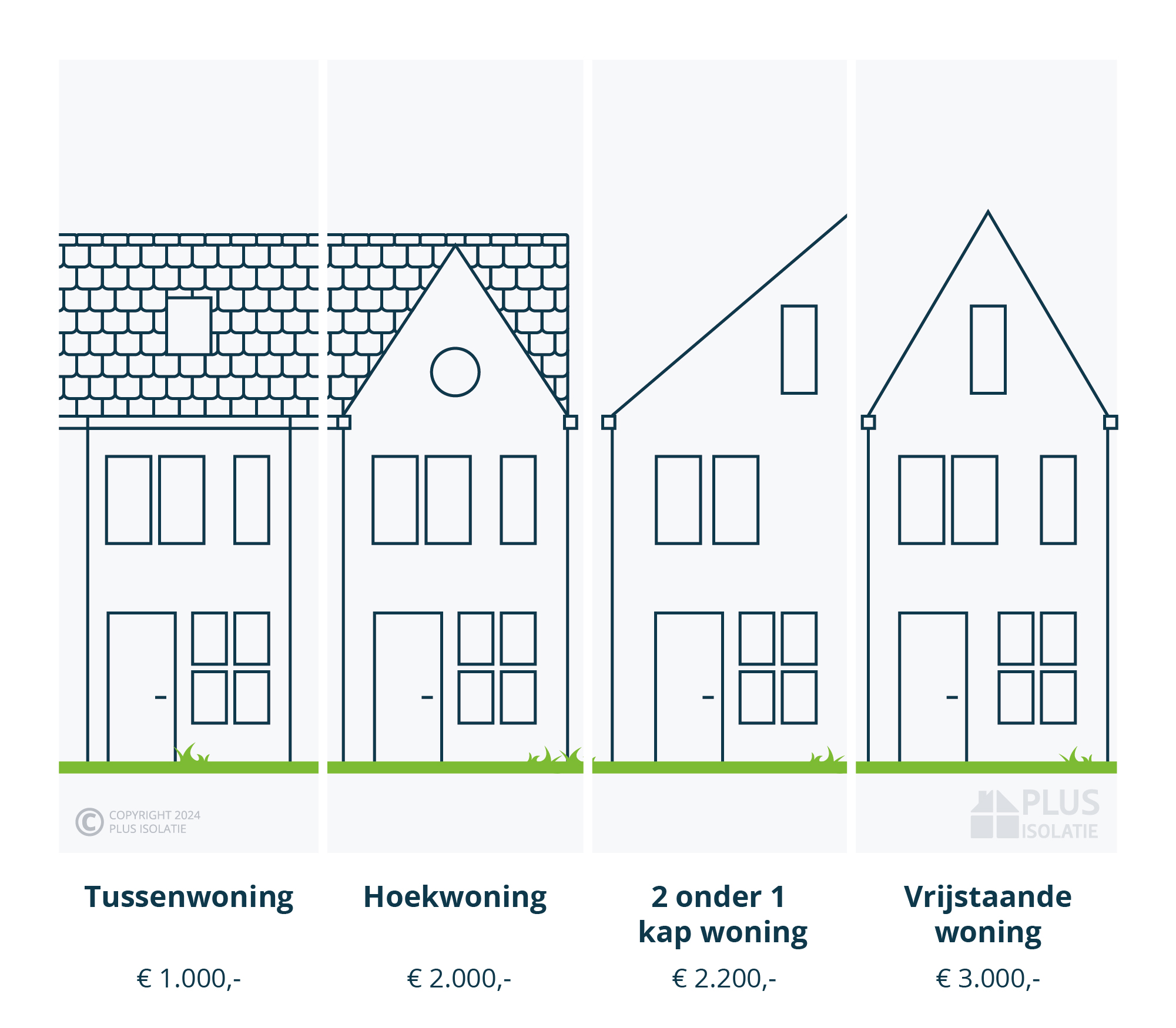

What cost cavity wall insulation?

The cost of cavity wall insulation varies per dwelling. This has to do with, among other things, the cavity wall area, the cavity wall width, the accessibility of the house, the insulation material and other costs (think of ventilation grids, cavity pollution removal or cut joint repair). The table below gives an indication of the average cost of cavity wall insulation:

What is the average payback time of cavity wall insulation:

The average payback time of cavity wall insulation is on average 3 to 5 years. This average

depends on the outside temperature. With a severe winter one fires more than with a mild

winter. The type of house is also important. In general, the more insulated square meters of

cavity wall, the faster the payback time.

Subsidy options for cavity wall insulation.

At the moment there is a subsidy available from the central government for cavity wall insulation, among other things. You need to combine the cavity wall insulation with another insulation measure. The subsidy you get back depends on the square meters to be insulated. There is at this moment a subsidy called ISDE Subsidie. You get €4 euro subsidy per m2 cavity wall insulation. If you decide to insulate more than one measure, than you get the double of that amount.

Free advice about cavity wall insulation.

If you contact Plus Insulation, an advisor will come to your home for free insulation advice. By means of an endoscopic examination the cavity will be checked to see if there is no construction waste or waste mortar in it. The facing bricks are also checked for frost damage and the joints are checked for cracks or porosity. Free Advice.

Call me back